Thermowells: An Overview

Thermowells are tubular fittings designed to protect Temperature sensors installed in industrial processes. They serve as a barrier between the process environment and the sensing element, such as thermocouples, RTDs, or thermometers. A thermowell consists of a closed-end tube inserted into the process stream, while the Temperature sensor is placed into the open end from the outside, typically remaining in ambient conditions. This setup allows the process fluid to transfer heat to the thermowell, which then conducts the heat to the sensor.

Thermowells are essential for maintaining the integrity and accuracy of Temperature sensors in high-pressure, high-Temperature, and corrosive environments. They allow for sensor maintenance or replacement without interrupting the process, increasing safety and reducing downtime. Commonly used in power plants, chemical processing, refineries, and steel industries, thermowells play a critical role in industrial Temperature monitoring and control.

Working Principle

The working principle of a thermowell is based on indirect thermal conduction. The thermowell is inserted into the process where Temperature is to be measured, and the sensor is inserted into the thermowell’s bore. Heat from the process fluid transfers to the outer wall of the thermowell, then through its wall to the sensor inside. This indirect contact protects the sensor from direct exposure to aggressive media, mechanical wear, or pressure surges.

While there is a slight delay in response time compared to direct immersion sensors, thermowells offer the significant advantage of durability, safety, and the ability to replace or calibrate sensors without stopping the process.

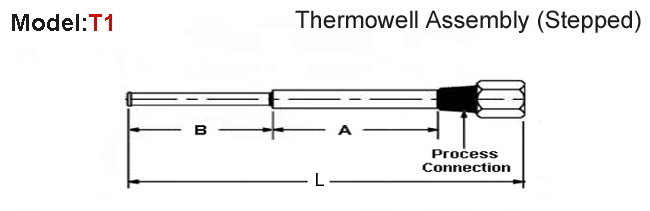

Model T1 – Manufactured by Ajmer Thermotech Pvt. Ltd.

Ajmer Thermotech Pvt. Ltd., an ISO 9001:2015 and CE certified company, manufactures and supplies the Model T1 thermowell assembly. This model features a stepped threaded design, engineered to enhance heat transfer efficiency while providing superior mechanical strength in threaded process connections.

The stepped construction of the Model T1 reduces tip mass, enabling faster thermal response, while the threaded mounting ensures secure installation in pipelines, vessels, or reactors. Designed for use in high-pressure and high-Temperature environments, this thermowell is ideal for safeguarding Temperature sensors such as thermocouples and RTDs from process-induced stress and corrosion.

Available in a variety of standard and custom thread sizes, lengths, and materials—including stainless steel and high-performance alloys—the Model T1 can be configured to meet specific application requirements. It is widely used in chemical processing, refineries, and general industrial systems where precision, safety, and ease of maintenance are critical.