Resistance Temperature Detectors (RTDs): An Overview

Resistance thermometers, commonly known as Resistance Temperature Detectors (RTDs), are highly accurate and reliable sensors used to measure Temperature by correlating the resistance of the RTD element with Temperature. They are widely used in applications where precision and stability are critical. Unlike thermocouples, RTDs operate based on the predictable change in electrical resistance of certain metals—most notably platinum—with Temperature.

RTDs are valued for their excellent repeatability, long-term stability, and accurate linear output over a broad Temperature range. They are commonly employed in laboratory, industrial, and commercial settings for Temperature monitoring and control, especially in processes requiring consistent and precise measurements.

Working Principle

The working principle of an RTD is rooted in the positive Temperature coefficient of electrical resistance exhibited by metals like platinum, nickel, or copper. As the Temperature increases, the resistance of the RTD element also increases in a known and repeatable manner.

An RTD element typically consists of a fine wire wrapped around a ceramic or glass core. The resistance is measured using a Wheatstone bridge or similar circuit, and the corresponding Temperature is derived based on standardized resistance-Temperature characteristics (such as the DIN EN 60751 standard for platinum RTDs).

Due to their stable and accurate behavior, RTDs are widely used where precise Temperature monitoring is essential, such as in power plants, refineries, chemical plants, and aerospace applications.

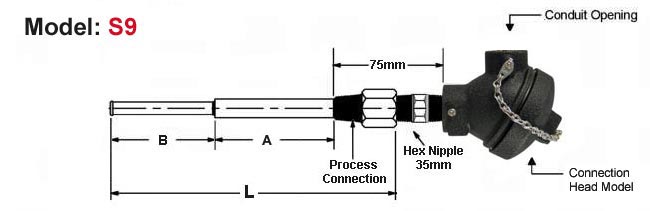

Model S9 – Manufactured by Ajmer Thermotech Pvt. Ltd.

Ajmer Thermotech Pvt. Ltd., an ISO 9001:2015 and CE certified company, manufactures and supplies the Model S9 RTD assembly with a standard stepped threaded thermowell. This model is specifically designed to offer enhanced mechanical strength and optimal thermal response in threaded process connections.

The stepped construction of the thermowell minimizes the tip mass, promoting faster heat transfer to the RTD sensor, while maintaining durability in high-pressure and high-velocity flow environments. The threaded design ensures secure and leak-proof installation in pipelines, tanks, and process vessels, simplifying sensor replacement and maintenance without disturbing the process.

Model S9 is available with various stem lengths, thread sizes, and material options such as stainless steel and high-Temperature alloys. Combined with high-accuracy RTD elements in 2-wire, 3-wire, or 4-wire configurations, the assembly meets a wide range of industrial requirements with precision and reliability.

Well-suited for applications in chemical plants, refineries, pharmaceuticals, and power generation, the Model S9 provides a robust and accurate solution for continuous Temperature monitoring in demanding environments.