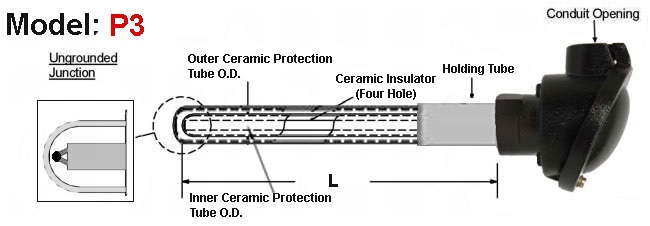

Model : P3

Noble Metal Thermocouple with Double Ceramic Protection Tube Assembly

Thermocouples: An Overview

A thermocouple is an electrical device consisting of two dissimilar electrical conductors that form junctions at differing Temperatures. When subjected to a Temperature gradient, a thermocouple produces a small voltage due to the thermoelectric effect. This voltage is Temperature-dependent and can be interpreted using standard reference tables or instruments to accurately measure Temperature. Owing to their simplicity, durability, and ability to function without external power, thermocouples are widely used in a range of industrial, scientific, and commercial applications.

Working Principle

The fundamental working principle of a thermocouple lies in the Seebeck effect, where a voltage is generated at the junction of two dissimilar metals when exposed to a Temperature difference. One junction (the hot junction) is placed at the measurement site, while the other (the cold or reference junction) remains at a known Temperature. The voltage generated is proportional to the Temperature difference between these two junctions and is used to determine the unknown Temperature. Accurate Temperature readings are possible with proper cold junction compensation and reference standards.

Type R, S, and B Thermocouples

Type R Thermocouples are composed of a Platinum (Pt) and Platinum-Rhodium (Pt-13%Rh) combination. They are known for their high accuracy (±0.25%) and stability, typically used for Temperature measurement in the range of 0 to 1600°C. Due to their reliability, Type R thermocouples are often used in critical and high-precision applications, including laboratories and high-Temperature furnaces.

Type S Thermocouples, similar in composition to Type R but with a 10% Rhodium component (Pt-10%Rh), also provide exceptional accuracy (±0.25%) and can operate up to 1600°C. They are widely used in the pharmaceutical, glass, and semiconductor industries where high precision is essential.

Type B Thermocouples are made from Platinum and Platinum-30% Rhodium. They are particularly suited for extremely high-Temperature environments, capable of measuring Temperatures up to 1800°C with an accuracy of ±0.50%. Their performance at high Temperatures and excellent stability make them ideal for applications such as steel and ceramic manufacturing.

Model P3 – Manufactured by Ajmer Thermotech Pvt. Ltd.

Ajmer Thermotech Pvt. Ltd., an ISO 9001:2015 and CE certified company, manufactures the Model P3 Noble Metal Thermocouple with Double Ceramic Protection Tube Assembly. This model is specifically designed for high-Temperature applications that demand superior insulation, extended service life, and optimal protection for the sensing elements.

The Model P3 incorporates noble metal thermocouple elements—commonly Type R, S, or B—housed within a double ceramic protection tube structure. The inner and outer ceramic tubes offer exceptional thermal and chemical resistance, shielding the thermocouple from harsh process conditions such as corrosive gases, high thermal cycling, and mechanical wear.

Ideal for use in furnaces, kilns, incinerators, and other extreme heat applications, the double ceramic design of the Model P3 ensures enhanced durability and measurement reliability. Ajmer Thermotech customizes the thermocouple based on client requirements, including tube length, material grade, junction type, and terminal configuration. The Model P3 exemplifies precision engineering and rugged construction, making it a trusted solution for critical Temperature measurement tasks in challenging environments.