Thermocouples: An Overview

A thermocouple is a widely used Temperature sensor that operates on the principle of the thermoelectric effect. It consists of two dissimilar electrical conductors that form junctions at different Temperatures. When these junctions are exposed to a Temperature difference, a voltage is generated that corresponds to the Temperature differential. This voltage, which arises due to the Seebeck effect, can be measured and interpreted to determine Temperature. Thermocouples are known for their durability, simplicity, fast response, and ability to measure a wide range of Temperatures. They do not require external power and can operate reliably in harsh environments, making them ideal for use in industrial, scientific, and commercial settings.

Working Principle

The operating principle of a thermocouple is based on the generation of a thermoelectric voltage when two dissimilar metals are joined at two points, forming a closed loop. One junction is placed at the point where Temperature is to be measured (hot junction), while the other is kept at a known reference Temperature (cold junction). The Temperature difference between these two junctions causes a small voltage to be produced, which can then be correlated to a specific Temperature using thermocouple reference tables or specialized electronic instruments with built-in cold-junction compensation. The accuracy and reliability of this measurement technique have made thermocouples a staple in Temperature monitoring and control systems.

Mineral Insulated Thermocouples (MI Thermocouples)

Mineral Insulated Thermocouples, also known as MI Thermocouples, are specialized sensors constructed using mineral insulated cable to provide enhanced mechanical and environmental protection. These cables consist of one (simplex) or two pairs (duplex) of thermocouple wires encased within a metal sheath. The interior is filled with high-purity magnesium oxide (MgO) powder, which acts as an insulator and provides excellent heat transfer properties.

The compacted structure of MI thermocouples ensures that the wires remain electrically insulated from each other and the outer sheath while maintaining superior mechanical strength and vibration resistance. The design is ideal for high-Temperature, high-pressure, or high-vibration environments. MI thermocouples are widely used in industries such as power generation, petrochemicals, metallurgy, and aerospace, where precision and rugged performance are critical.

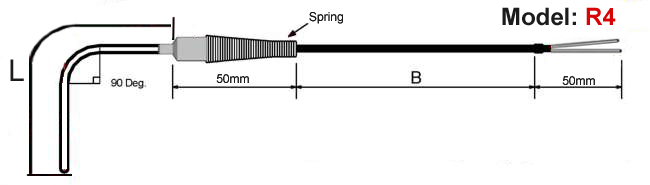

Model R4 – Manufactured by Ajmer Thermotech Pvt. Ltd.

Ajmer Thermotech Pvt. Ltd., an ISO 9001:2015 and CE certified company, manufactures and supplies the Model R4 M.I. Bend Thermocouple. This model is a flexible and rugged Temperature sensing solution featuring a mineral insulated (M.I.) construction with a pre-formed bend to suit space-constrained or angled installation environments. The bent design allows for easy routing around obstacles and ensures precise sensor placement within the process.

The Model R4 provides excellent mechanical strength, fast thermal response, and high resistance to vibration and harsh conditions. Its mineral insulation, filled with compacted magnesium oxide, ensures electrical insulation between the conductors and sheath while enhancing heat transfer efficiency.

Ajmer Thermotech offers the Model R4 in a range of thermocouple types (such as K, J, T, or N), sheath diameters, bend angles, and lengths, allowing it to be tailored to customer-specific requirements. It is widely used in industries such as chemical processing, metalworking, power generation, and laboratory systems where space limitations demand a compact and flexible sensing solution. With proven durability and consistent performance, the Model R4 ensures accurate and reliable Temperature measurement in demanding applications.