Special Thermocouples: An Overview

Special thermocouples are designed for demanding and highly specific industrial applications where standard configurations may not suffice. These sensors are engineered with enhanced protection, customized assemblies, and application-focused materials to ensure accuracy, reliability, and longevity under extreme conditions. Whether operating in molten metal environments, fluidized beds, or specialized furnaces, special thermocouples are built to meet the unique thermal, mechanical, and chemical challenges of the process.

Working Principle

Like standard thermocouples, special thermocouples operate based on the Seebeck effect. Two dissimilar metals form a thermoelectric circuit; when the two junctions are at different Temperatures, a voltage is generated that corresponds to the Temperature difference. This voltage can be measured and converted into Temperature using standard calibration data. What distinguishes special thermocouples is their robust construction, protective assemblies, and optimized materials suited to extreme industrial applications.

Type R thermocouples consist of a Platinum (Pt) and Platinum-13% Rhodium (Pt-Rh) combination. They are used extensively in high-Temperature environments (0°C to 1600°C) and offer exceptional accuracy (±0.25%) and stability. They are ideal for use in metallurgy, glass, and ceramic industries due to their resistance to oxidation and thermal shock.

Type B thermocouples are made of Platinum-30% Rhodium and Platinum-6% Rhodium. Designed for extremely high Temperatures (up to 1800°C), they are commonly used in high-Temperature furnaces and molten metal applications. They have excellent long-term stability and an accuracy of ±0.50%, making them suitable for continuous use in extreme environments.

Type S thermocouples are composed of Platinum and Platinum-10% Rhodium and offer similar performance to Type R. They operate accurately up to 1600°C and are commonly used in laboratories, metal processing, and pharmaceutical environments where high accuracy (±0.25%) is essential.

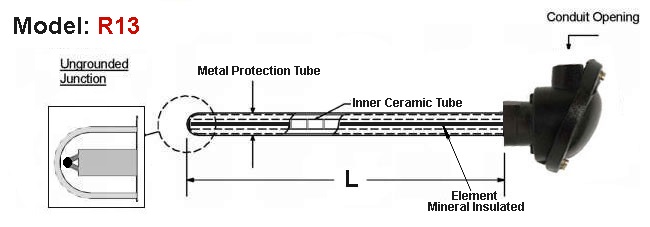

Model R13 – Fluid Bed Thermocouple with Metal Protection Tube Assembly

Ajmer Thermotech Pvt. Ltd., an ISO 9001:2015 and CE certified company, presents the Model R13, a special-purpose thermocouple designed for fluidized bed furnace applications. This thermocouple is specifically engineered to withstand the abrasive and high-velocity environment inside fluid bed reactors and furnaces, commonly used in industries like metallurgy, chemical processing, and power generation.

The R13 model incorporates a mineral insulated (M.I.) thermocouple element housed within a durable metal protection tube, which shields the sensing element from mechanical erosion, chemical corrosion, and fluid bed particle impact. This assembly ensures long-term accuracy and reliability, even in environments with high turbulence and fluctuating Temperatures.

Ajmer Thermotech offers R13 in various thermocouple types (such as K, J, or N), with full customization including sheath diameter, length, metal alloy (like SS310, Inconel), cold end termination options, and mounting accessories. The design can also include reinforced construction or wear-resistant coatings based on user needs.

This specialized thermocouple ensures optimal thermal responsiveness and durability, making the Model R13 an ideal solution for continuous Temperature monitoring in demanding fluidized bed processes.