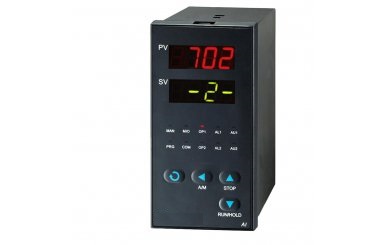

Model PD1 – Digital Autotune PID Controllers

Overview

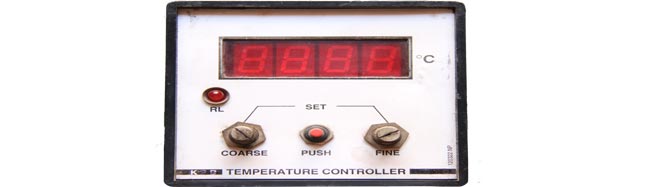

PID (Proportional–Integral–Derivative) controllers are fundamental instruments used in industrial automation to maintain desired process conditions such as Temperature, pressure, or flow rate. By continuously comparing a setpoint to the process variable and applying corrective actions, PID controllers ensure optimal system performance with minimal manual intervention.

Working Principle

A PID controller calculates the deviation (error) between a desired setpoint and a measured process variable. It applies corrective output based on three components:

Proportional (P): Immediate response to the current error

Integral (I): Correction based on accumulated past errors

Derivative (D): Predictive correction based on the rate of error change

This tri-action logic enables the controller to stabilize the process efficiently and accurately. The autotune function automatically adjusts PID parameters to suit the system’s dynamics, minimizing overshoot and improving stability.

Key Features

Control Outputs:

Servomotor

On/Off Relay

4 to 20 mA Analog Output

Profile Control:

Programmable 16-segment Ramp-Soak profile for complex Temperature/time operations

Alarm Outputs:

Up to 2 alarms

230 VAC, 3 Amp relay contacts

Fuzzy Logic & Autotuning:

Advanced fuzzy logic-based PID algorithm for adaptive and self-correcting performance

Automatic tuning of PID parameters ensures easy setup and optimum response

Universal Input Compatibility:

Thermocouple (e.g., K, J, T, etc.)

RTD (PT-100)

Analog (4 to 20 mA)

Available Sizes:

48 × 48 mm

48 × 96 mm

96 × 48 mm

96 × 96 mm

Additional Features:

Remote Set Point (RSP) functionality

Retransmission Output for signal duplication

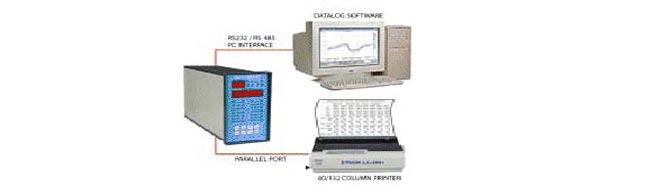

Serial Communication: RS-485 / RS-232 for SCADA or PLC integration

Applications

Temperature control in furnaces, ovens, and heating systems

Flow and pressure regulation in industrial processes

Automation in plastic, packaging, and chemical industries

Systems requiring ramp-soak programming and adaptive tuning