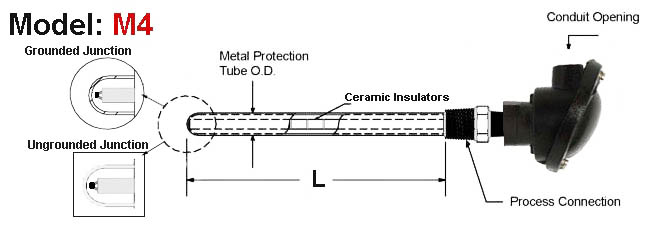

Model : M4

Base Metal Thermocouple in Metal Protection Tube Assembly with Process Connection

Thermocouples: An Overview

A thermocouple is a widely used Temperature sensor that operates on the principle of the thermoelectric effect. It consists of two dissimilar electrical conductors that form junctions at different Temperatures. When these junctions are exposed to a Temperature difference, a voltage is generated that corresponds to the Temperature differential. This voltage, which arises due to the Seebeck effect, can be measured and interpreted to determine Temperature. Thermocouples are known for their durability, simplicity, fast response, and ability to measure a wide range of Temperatures. They do not require external power and can operate reliably in harsh environments, making them ideal for use in industrial, scientific, and commercial settings.

Working Principle

The operating principle of a thermocouple is based on the generation of a thermoelectric voltage when two dissimilar metals are joined at two points, forming a closed loop. One junction is placed at the point where Temperature is to be measured (hot junction), while the other is kept at a known reference Temperature (cold junction). The Temperature difference between these two junctions causes a small voltage to be produced, which can then be correlated to a specific Temperature using thermocouple reference tables or specialized electronic instruments with built-in cold-junction compensation. The accuracy and reliability of this measurement technique have made thermocouples a staple in Temperature monitoring and control systems.

Type K Thermocouple

Type K is the most commonly used thermocouple for general-purpose Temperature measurement. It is made from a combination of Nickel-Chromium (Chromel) and Nickel-Aluminum (Alumel). With a Temperature range of approximately −200°C to +1300°C, Type K is suitable for a broad spectrum of industrial applications. It has a sensitivity of about 41 microvolts per degree Celsius and an accuracy of ±0.75 percent. Due to its stability and resistance to oxidation, Type K performs well in environments with oxidizing or inert atmospheres. It is commonly used in applications such as metal processing, furnaces, chemical plants, and power generation systems.

Type J Thermocouple

Type J thermocouples are made from Iron and Constantan (a copper-nickel alloy). Although they have a more limited Temperature range, from approximately −40°C to +750°C, they offer higher sensitivity than Type K, producing about 50 microvolts per degree Celsius. Type J also has an accuracy of ±0.75 percent. It is particularly well-suited for use in environments where high sensitivity is required at lower Temperatures. However, it should be noted that Type J is less suitable for oxidizing atmospheres at high Temperatures, as the iron conductor can oxidize quickly. Type J thermocouples are often found in the plastics industry, food processing, laboratory equipment, and other controlled settings.

Model M4 – Manufactured by Ajmer Thermotech Pvt. Ltd.

Ajmer Thermotech Pvt. Ltd., an ISO 9001:2015 and CE certified company, manufactures and supplies the Model M4 thermocouple. This model is a base metal thermocouple housed in a robust metal protection tube assembly with a process connection, designed for secure and long-lasting Temperature measurement in demanding industrial environments. The Model M4 offers enhanced mechanical strength and chemical resistance, making it suitable for applications where the thermocouple is exposed to physical stress, corrosive media, or high-velocity flow. The protective metal sheath shields the thermoelements from damage, while the integrated process connection ensures safe and reliable installation into pipelines, tanks, or process equipment.

The Model M4 is available in multiple configurations and can be tailored to meet specific industrial requirements, including thermocouple type, protection tube material, process connection size and type, insertion length, junction style, and lead wire termination. Each unit is manufactured to precise customer specifications to ensure compatibility and performance in the field. Whether used in chemical processing, power plants, oil and gas systems, or other high-demand process industries, the Model M4 delivers accurate, stable, and dependable Temperature readings. Ajmer Thermotech’s focus on quality craftsmanship and application-specific solutions has made it a preferred partner for Temperature sensing products in critical process environments.

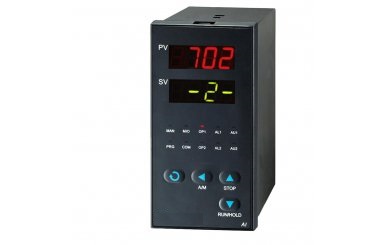

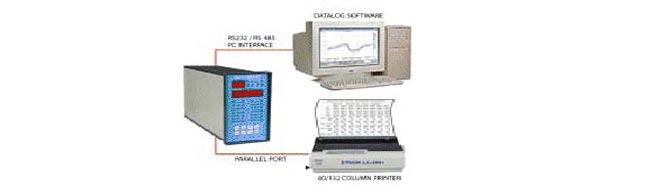

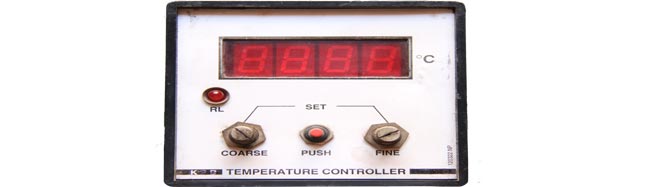

Related Products

About Ajmer Thermotech Pvt. Ltd.

With a legacy spanning over 25 years, Ajmer Thermotech Pvt. Ltd., based in Ajmer, Rajasthan, is one of India’s trusted names in the field of Temperature sensing and industrial instrumentation. We specialize in manufacturing and supplying a comprehensive range of precision-engineered products including Thermocouples, RTDs, Temperature Indicators, PID Controllers, Temperature Transmitters, Data Loggers, Infrared Thermometers, Optical Pyrometers, and various custom-built solutions tailored to meet diverse industrial requirements.

Our solutions are widely used across industries such as steel, foundries, cement, power, chemical, pharmaceuticals, food processing, glass, and more—ensuring consistent performance even in the most demanding environments. From compact handheld thermometers to complex multi-channel scanning and data acquisition systems, our offerings are built for accuracy, durability, and ease of integration. Driven by innovation and backed by deep technical expertise, our team focuses on delivering quality-tested, cost-effective products with exceptional service support.

At Ajmer Thermotech, we pride ourselves on our ability to adapt and evolve, offering both standard and custom Temperature measurement systems that empower industries of all shapes and sizes to operate with precision and reliability. We are ISO-compliant and committed to continual improvement, ensuring our customers benefit from the latest advancements in Temperature monitoring and control.

- Copyrights reserved © 2025